|

SOLD BY EQUIPMENT DEALERS SOLD BY EQUIPMENT DEALERS

All Baumalight products are sold through our network of equipment dealers. For you, this means better product support, after-sales service, maintenance and product warranty from your local, trusted dealership

|

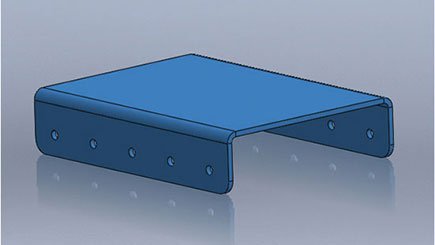

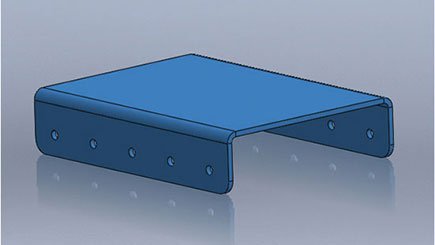

Excavator Mount Excavator Mount

This standard mounting plate is perfect for welding to your skid steer’s unique fitting.

|

|

Bent Axis Motor Bent Axis Motor

Our Industry leading bent axis piston motors make the most efficient use of your hydraulic flow and pressure for your brush clearing needs.

|

HIGH SPEED TEETH HIGH SPEED TEETH

The concave shaped carbide tip of our High Speed Teeth provide aggressive cutting action by chipping the brush bit by bit. This round tooth is 3 teeth in 1. Simply loosen the lock nut and rotate the tooth to a fresh, sharp cutting edge. This can be done three times, extending the life of each tooth.

|

|

FREE TEETH FREE TEETH

The GXM750 Stump Grinder comes with 3 free replacement teeth and 1 extra teeth holder. These replacement teeth can be conveniently stored in the spare tool compartment.

|

|

More Teeth More Teeth

The high number of teeth means that each tooth needs to do less work. Each of the Stump Blasters teeth only need to make a small cut, because the work is shared by more of our rugged teeth they last longer and usually only require 2 or 3 replacements at a time. The bolt-on designed teeth allow for straightforward replacement.

|

Blast Shield Blast Shield

The extra-large blast shield provides maximum chip and debris control with a dual row of safety chain curtains. The blast shield can also be used for cleanup and back filling without getting out of your cab.

|

|

More Clearance More Clearance

The Stump Blaster’s carbide teeth extend a full 1-¼ inches from the rotor. This prevents chips and mulch from getting plugged. More chip clearing produces smoother operation and reduces heat build-up that can damage the rotor and cause premature tooth failure.

|

Rotor

The massive ¾" thick steel rotor provides the back bone for the Stump Blaster cutting system. It’s the anchor for the carbide tipped teeth. For smooth operation it’s important that the rotor remains solid, with no flexing. The rugged rotor also provides the Stump Blaster with the extra momentum needed when the grinding is tough, making sure the Stump Blaster can power through the hardest stumps.

|