RENN Roller Mill RMC 48

|

|

|

Specifications

|

Model |

RMC

|

Category Name |

Agriculture

|

Year |

2023

|

|

Sale Type |

New

|

Manufacturer |

Renn

|

PTO Std. * |

540/1000

|

|

Min. (PTO) HP |

110

|

Roll WxD (in.) |

48x16

|

Auger Discharge |

12" or 14"

|

|

Hyd. Feed Auger |

12"

|

Shaft Dia. (in.) |

2 ¹⁵⁄₁₆

|

Conveyor Discharge |

18"

|

|

Elevator Discharge |

8" x 10'

|

Differential Roll Speed ** |

2x 8cc belt

|

Price |

Contact for price CAD

|

| |

|

|

|

Description

|

RENN Roller Mills can be tailored to meet the needs of any grain processing application.

We offer two different types of rolls – steel or cast; multiple roll configurations ranging from 4 to 15 grooves per square inch depending on the particle size you require – and a variety of input and discharge options, including our Elevator Discharge or Crimper Mill, Blower Discharge Mill, Conveyor Discharge Mill, Electric Roller Mill, and Auger Discharge Mill. We offer so many choices so that we can build a Roller Mill that is perfectly designed to consistently meet the specific grain processing needs of your dairy or beef herd.

Whether you need a coarse crack or a fine grind, our Roller Mills consistently produce the high-quality feed that farmers have come to expect from RENN.

|

Maximize Productivity Maximize Productivity

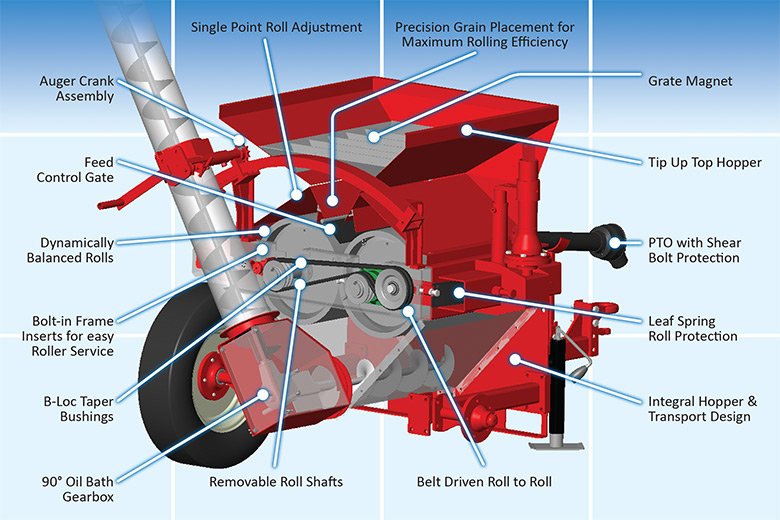

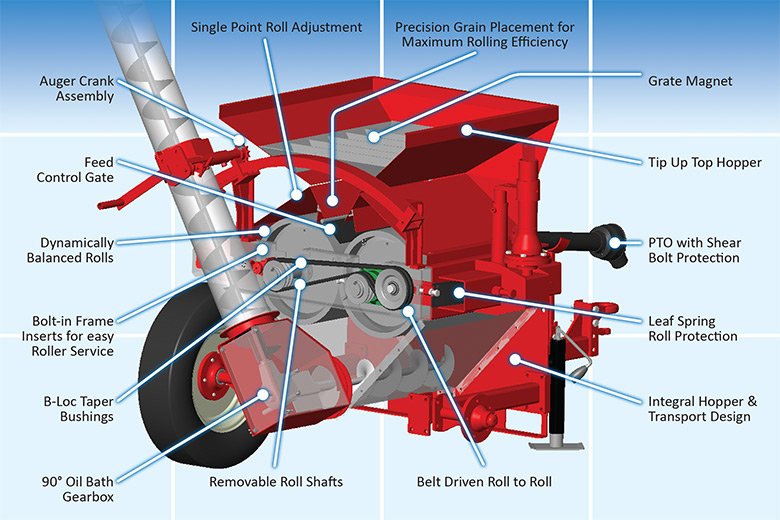

RENN Roller Mills have a proven record of excellence in the grain processing industry for maximizing productivity while providing durable, consistent performance and easy serviceability.

RENN’s unique, centrifugally-poured, chill-cast rolls are its latest advancement in rolling technology, giving you the long-wearing durability of cast rolls with the enhanced serviceability of removable shafts and end plates.

|

Lower Power Requirement

Unlike conventional, solid-core cast rolls, our 16” diameter casting with a 3” thick sidewall provides the performance of chill-cast rolls with the advantage of a lower power requirement and better economics, as you are no longer paying for the unusable centre core of the roll.

The RENN Roller Mill design ensures operator efficiency and time-saving serviceability. The RENN worm drive roll adjustment allows for easy roll gap adjusting while the RENN leaf spring holds the rolls in place for maximum rolling capacity. The rolls can be pulled for service in minutes due to RENN’s tip-up top hopper and split frame design, making it fast and easy to re-groove and re-install them, for thousands more tonnes of trouble-free rolling.

|

|

RENN Roller Mill Features RENN Roller Mill Features

|

Elevator Discharge Mill/Crimper Mill Elevator Discharge Mill/Crimper Mill

The optional RENN 40% Differential Drive has idler and driver rolls positively driven at two different speeds for optimal particle reduction or high moisture rolling. It is also self-cleaning to prevent plugging. RENN Roller Mills are available in PTO powered trailer or Electric Stationary models, and offer various input, power, and discharge options. PTO models have a minimum power requirement of 15 to 120 horsepower, while Electric Stationary units operate with a minimum power requirement of 5 to 50 horsepower.

|

|

|

|

DISCHARGE SYSTEMS

|

Discharge_Systems

Auger Discharge

Built for operator efficiency and serviceability, it comes in 7”, 8”, 10” and 12” diameter sizes and is available in most RMC models.

Elevator Discharge/Crimper

With exceptional capacity in extreme high moisture rolling conditions, the unit is 8” wide X 10’ high and is available in most RMC models.

Blower Discharge

RENN offers the industry’s largest and heaviest unit with a high-capacity 59” diameter, 8 blade blower that is available in most RMC models.

Conveyor Discharge

Designed to process large volumes of high moisture grains quickly, the 18” wide conveyor is available with RMC 36” and 48” models. Our 24” wide conveyor is available with RMC 36” and 48” tandem models. |

|

|

MAXIMUM DRY RATED GRAIN CAPACITY

|

Corn_t/hr

134

Oats_t/hr

17

Corn_bu/hr

5000

Oats_bu/hr

1000

Wheat_t/hr

54

Barley_t/hr

26

Wheat_bu/hr

2000

Barley_bu/hr

1200

|

|

LITERATURE

|

Literature

| Name |

Link |

| Renn_RollerMill_Brochure_Sept2018 |

Download |

|